QDJ-2600BPractical type thread touching intelligent automatic nail bonding machine

1.Main components:

(Note: Some parts of the brand of the update may change, please refer to the machine installation prevail.)

| serial number | name | brand | remark |

| 01 | Head servo motor | Mitsubishi, Japan | 2platform |

| 02 | Paper feeding servo motor | Mitsubishi, Japan | 1platform |

| 03 | Pat the servo motor | Yaskawa, Japan | 1platform |

| 04 | Touch the servo motor | Mitsubishi, Japan | 1platform |

| 05 | Head reducer | Taiwan Li Ming | 1platform |

| 06 | Bump line reducer | Faston, France | 1platform |

| 07 | Leading edge reducer | Faston, France | 1platform |

| 08 | PLC, photoelectric switches and proximity switches | Japanese Omron | |

| 09 | Contactors, circuit breakers, frequency converters | Mitsubishi, Japan | |

| 10 | Intermediate relays | Schneider, France | |

| 11 | The whole set of nail heads | Taiwan parts assembly | |

| 12 | Cylinders, solenoid valves | Taiwan Adecco | |

| 13 | touch screen | Taiwan Weilun Tong | |

| 14 | blade | Made of German alloy tungsten steel | Abrasion resistant |

| 15 | Base mold | Made of German alloy tungsten steel | Corrosion resistant |

2.Details:

The practical thread touching intelligent automatic nail bonding machine is composed of six parts: paper feeding part, wire touching part, folding part, nail box part, counting output part and electrical control department. PLC control touch screen input data, nail box action servo motor control, simple and reliable operation. Automatic paper supply, automatic line touching, automatic folding, automatic correction, automatic nailing, automatic counting, automatic stacking output, before and after the whole machine, synchronous adjustment, order storage, the difference between the work drawbacks of the sticky box machine and the nail box machine assembly machine, the main nail sticking up and down automatic separation, one-key conversion, left and right traverse, nail gluing work when running independently, adjustment is more convenient, fast and efficient. Advanced technology, reliable quality.

A、Paper feeding department:

The use of West Green high wear resistant suction belt, each can individually control the size of the air volume. To ensure the stability of adsorption, the paper feeding department adopts double transmission servo before and after separating the paper feeding, and the pre-pressure synchronous automatic adjustment is carried out simultaneously, and each cardboard is individually and accurately transported before and after, and the positioning is more accurate. The front bezel of the paper supply department is electrically adjusted left and right, and the front paper feeding part is electrically adjusted, which is suitable for the paper supply needs of various specifications of the carton, which is convenient and fast.

The paste box adopts the glue coating method under the knurled wheel, which is evenly coated, no leakage and gum saving. The glue coating part is equipped with the upper and lower pre-pressing of the cardboard tongue twice to make its carton molding more standard.

B、Touch line:

The cardboard is sent out from the paper feeding department to the thread touching department for threading, which is a feature of our company’s nail gluing machine. After the base paperboard comes down from the previous process, the rolling effect is often not ideal, which affects the quality of the product. The thread touching part is to re-process the original rolling wire part with the method of touching the wire, so as to achieve a better folding effect, and the size of the carton after the nail can be well controlled.

Our company’s wire bumper adopts the most reasonable structure, the key data is based on countless tests and tests, of which the line pressure can be adjusted according to the thickness and material of the paperboard, so the wire section has the advantages of reasonable structure, novel design, practical convenience, obvious effect and so on.

C. Folding part

1. Interconnect with the touching part, adjust the frequency and speed of the frequency, install each forming wheel, and roll the original cable again.

2, the use of West Green porous belt conveyor cardboard, automatic folding, the whole process of adsorption, effectively avoid the weighting box, film box, glazing box and other paperboard in the work of the phenomenon of skewed slip paper pile, so that the whole machine is more stable and efficient.

D. Correction Department

1, the machine in the folding part of the nail box before the formation of a shaping device, in front of the nail box will be folded the carton again to make a shaping alignment, to ensure that the nailed out of the carton without scissors edge.

2. The correction department is driven by servo motor.

Nail box part

- The nail box head is made of special material, which is wear-resistant and not easy to damage.

- The feature of this machine is that the machine head adopts servo motor direct drive, and the speed is stable and accurate.

- The nail line adopts 2 plates of 20kg large plate flat wire automatic wire feeding device at a time to reduce the number of wire changes and improve production efficiency.

- The machine can implement single-nail, double-nail and reinforced nail multi-function operation on the carton.

- The nailing speed per minute can reach 700 nails/minute.

F, count, stacked output part

Complete the cartons, pat them again, count, stack and send them out automatically.

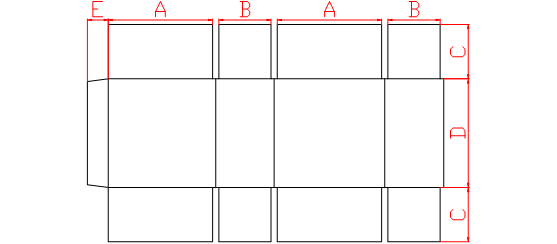

3.Main parameters:

| Model and parameters | QDJ-2600B+Pat enabled | QDJ-2600B+Pat enabled |

| Maximum size (A+B) X2(mm) | 2400(sticky)2600(nail) | 2600 |

| Minimum size (A+B) X2(mm) | 780 | 1060 |

| Maximum size (C+D+C)(mm) | 1200 | 1200 |

| Minimum size (C+D+C)(mm) | 340 | 530 |

| Minimum Shake Cap C(mm) | 25 | 25 |

| Maximum Shake Cap C(mm) | 320 | 320 |

| Maximum width B (mm) | 500 | 500 |

| Minimum Width B(mm) | 120(nail)80(sticky) | 250 |

| Maximum length A (mm) | 800 | 800 |

| Minimum Length A(mm) | 200 | 280 |

| Maximum height D (mm) | 650 | 650 |

| Minimum Height D(mm) | 200 | 200 |

| Tongue width E (mm) | 30-35 | 30-35 |

| Mechanical Length(mm) | 13000 | 13000 |

| Machine Width(mm) | 3800 | 3800 |

| Mechanical Weight(T) | 11.5 | 11.5 |

| Power of the whole machine(kw) | 22 | 22 |

| Mechanical speed (nails/min) | 700 | 700 |

| Subscription | 1-99 | 1-99 |

| Stud pitch(mm) | 30-80 | 30-80 |

| Nail box speed (three-port nail) | 50-60slice | 70-80slice |

| Adhesive box speed (m/min) | 120 | 120 |

Note: The position of the first nail is less than 145mm, and the minimum size of the pat is 530mm.

Touch part parameters:

| Maximum width B (mm) | 500 |

| Minimum Width B(mm) | 165(nail)140(sticky) |

| Maximum length A (mm) | 800 |

| Minimum Length A(mm) | 200 |

Headpiece parameters:

| Nail head speed | 700 pegs/min |

| Minimum cardboard thickness | 4mm |

| Maximum cardboard thickness | 12mm |

| U-shaped nail inner width | 12mm |

| Flat wire specifications | 17#(2.0×0.75) |

| Nail box inclination | 45 |

| Minimum peg spacing | 30mm |

Heap part parameters:

| The minimum stack width | 350mm |

| The maximum stack width | 1300mm |

| Minimum stack length | 460mm |

| The maximum stack length | 1200mm |

| velocity | 120m/min |